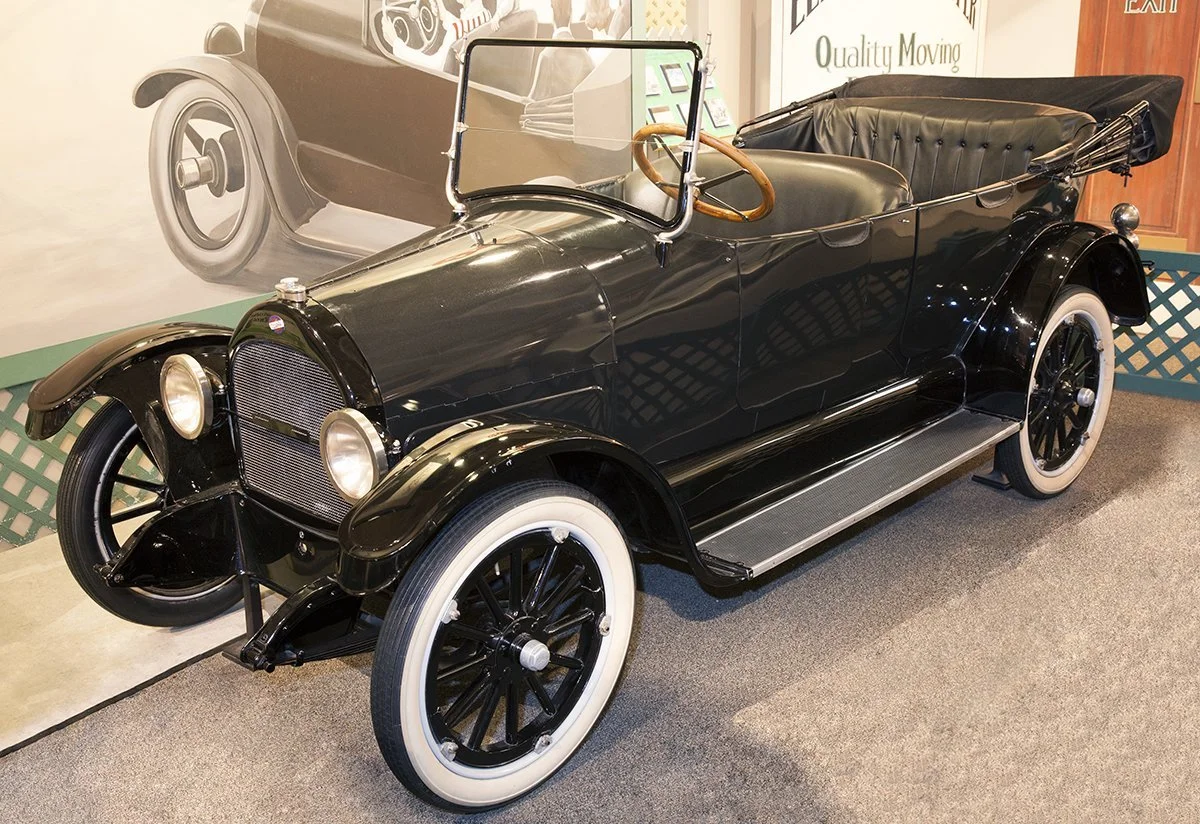

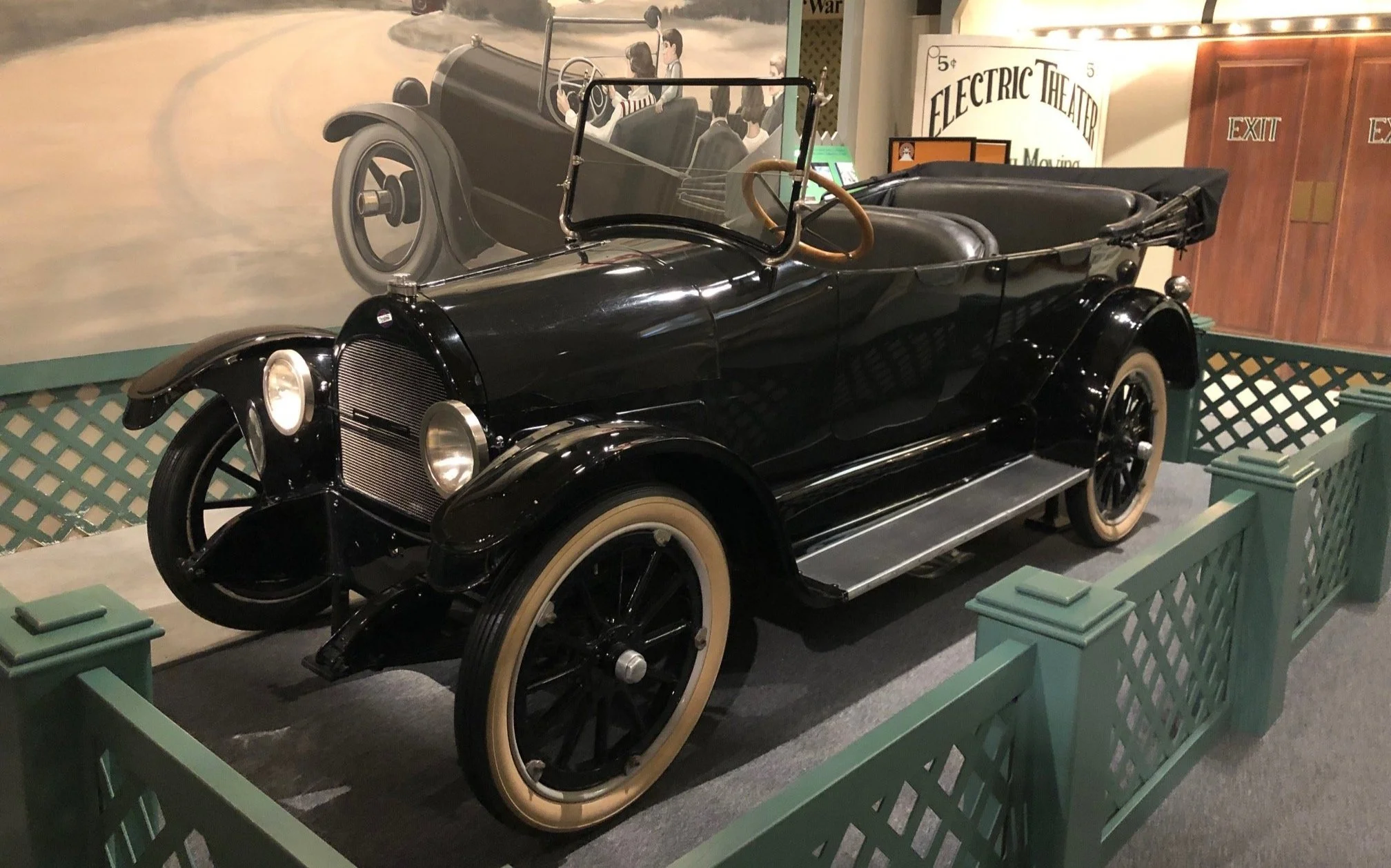

Overland Light 4 Touring Car

(Object ID: 99.22.1)

Project Duration: 45 Hours

Date: 1917

Dimensions: L: 162in W: 65in D: 66in

Materials: Enamel, steel, plastic, leather, textile, rubber, glass, wood

Object Description:

The Overland Automobile Company was founded by Claude Cox in Terra Haute, Indiana, in 1903 and moved to Indianapolis in 1905. John North Willys bought the failing firm in 1908, turned its fortunes around, and relocated the company to Toledo, Ohio. At $665, this four-cylinder Overland cost more than a Ford Model T, but it offered more style and comfort. Acquired specifically for Your Place in Time exhibit--used in a static, but "hands on" visitor experience.

Condition:

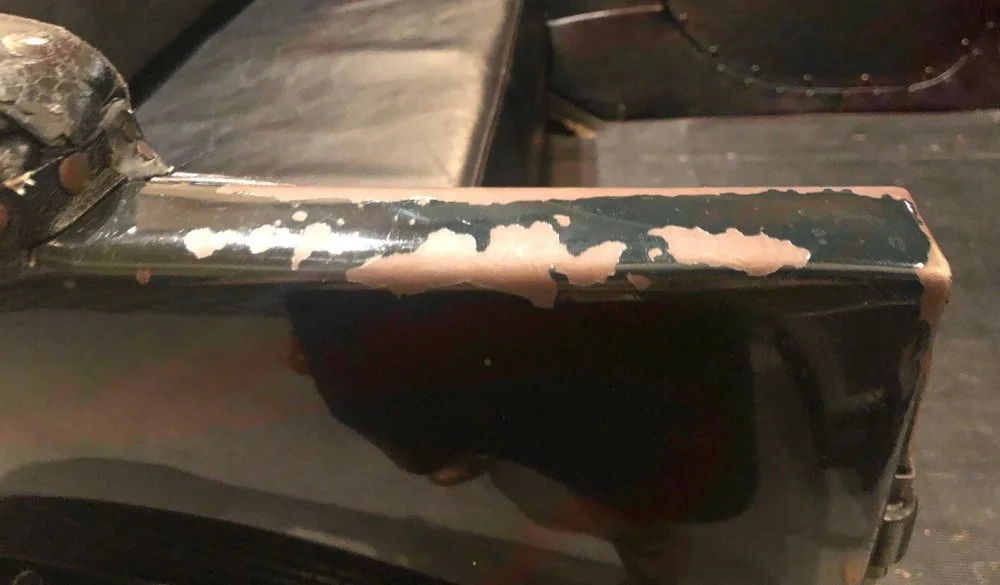

Due to constant use as an interactive object in the museum, the Overland has never received any conservation maintenance during its 22 years of being on display (apart from the seats of the vehicle). This wear is evident on the enamel paint, especially in locations such as armrests, fenders, and the running boards.

Severe enamel paint loss is present on the passenger side armrests and nearly all edges on the vehicle. It is assumed that during the car’s initial restoration, a different shade of green was used on the body. This can be seen on select areas of the vehicle, with the original color appearing to be a deep forest green, and the newer paint being distinguished as more of a muted green/grey. The fenders and running board of the vehicle are painted with black enamel and also possess multiple locations with chipping/abraded paint. The interior of the vehicle and doors are painted varying shades of dark green and black. This paint is worn throughout due to visitors stepping on or near the area so frequently.

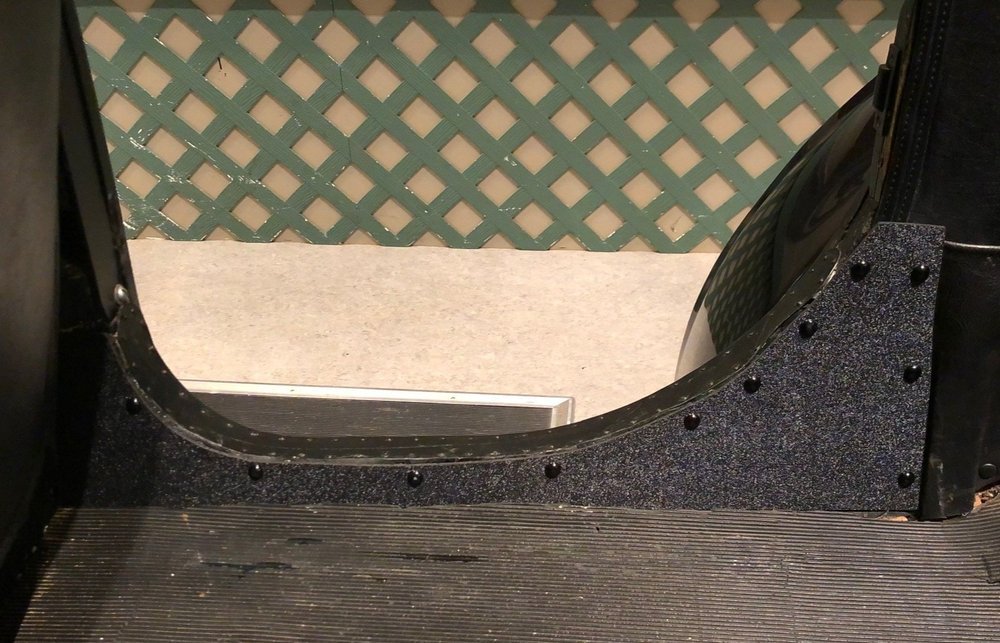

The door sill on the back seat of the passenger’s side is more severely worn; wood portions now have physical losses to them that affect how the interior vinyl lining connects to the vehicle. The vinyl lining on the door is also extremely tattered and must be replaced with a more durable material to continue sustaining such wear. The driver’s door interior lining (or door card) is also structurally degrading. The paper layers making up the panel have become delaminated and misshapen with use. Additionally, the vinyl covering has completely worn on the upper proper right corner of the lining and needs partial replacement. The adhesive connecting the vinyl armrests on the driver’s side to the door has degraded and is failing. The vinyl lining on the back of the driver’s seat is also experiencing similar adhesive failure and must be replaced.

Treatment:

All enamel paint losses on the body of the vehicle were in-painted with a mixture of Painters Supply & Equipment Co. acrylic enamels (labelled ‘special dark gray’ and ‘green’) and Testors Enamel Model Paints (in ‘gloss black’ and ‘gloss brown’). Two different mixtures were used for the differing shades of green on the body so that the color appeared as natural as possible. The fenders and running board were in-painted with Testors Enamel Model Paint in ‘gloss black’.

The losses on the door sill were vacuumed and cleaned using V&A mix (3% Orvus in 1:1 H2O and Mineral Spirits). All voids in the wood were filled with Abatron WoodEpox (2 part epoxy wood replacement compound). The wood filler was sanded down to shape then painted using Liquitex Artist Color Acrylic paints (Cadmium red extra deep, ivory black, and emerald green). Paint losses on other wood components were also in-painted with these colors to better match the original design. A new vinyl lining for the door sill was made using Acrylonitrile butadiene styrene (ABS) plastic, a much more durable material than vinyl that will be able to better sustain physical contact and wear with visitors.

The corner of the door card was removed from the vehicle and all paper layers were laminated together again using Jade 403. Additional archival card stock was attached to the back to reinforce the panel. A 5”x2” piece of replacement vinyl was cut to replace the degraded vinyl on the corner. Hollytex Japanese Tissue and Jade 403 were used to connect the new vinyl to the panel. A viscous paste consisting of Methyl Cellulose powder, Jade 403 adhesive, Liquitex artist’s acrylic (black), and distilled water was made and used to fill the connecting edges between the old and new vinyl for a more seamless finish.

Previous repairs to the driver’s side armrests were painted with Liquitex Artist Color Acrylic paints in black to better match the pieces. The failing adhesive on both the armrests and the vinyl lining on the back of the driver’s seat was removed using ethanol. New Very High Bonding (VHB) Tape was applied on the edges of the vinyl pieces to create a more secure bond to the car.