Ceramic Jar Rim

(No. 9984)

Project Duration: 25 Hours

Date: Iron Age II

Dimensions: 190 x 110 x 110mm

Materials: Ceramic

Object Description: The object is associated with the potters that created it, who were either local potters near the site or cooking pot traders that would travel to the region. The item is also associated with Dame Kathleen Kenyon, a notable English archaeologist who led numerous excavations in Jericho, Jordan, and Jerusalem. It is likely the piece was wheel thrown. Wheel thrown cooking pots were common practice in pottery production in Jerusalem during the Iron Age II, further supporting this theory.

Condition:

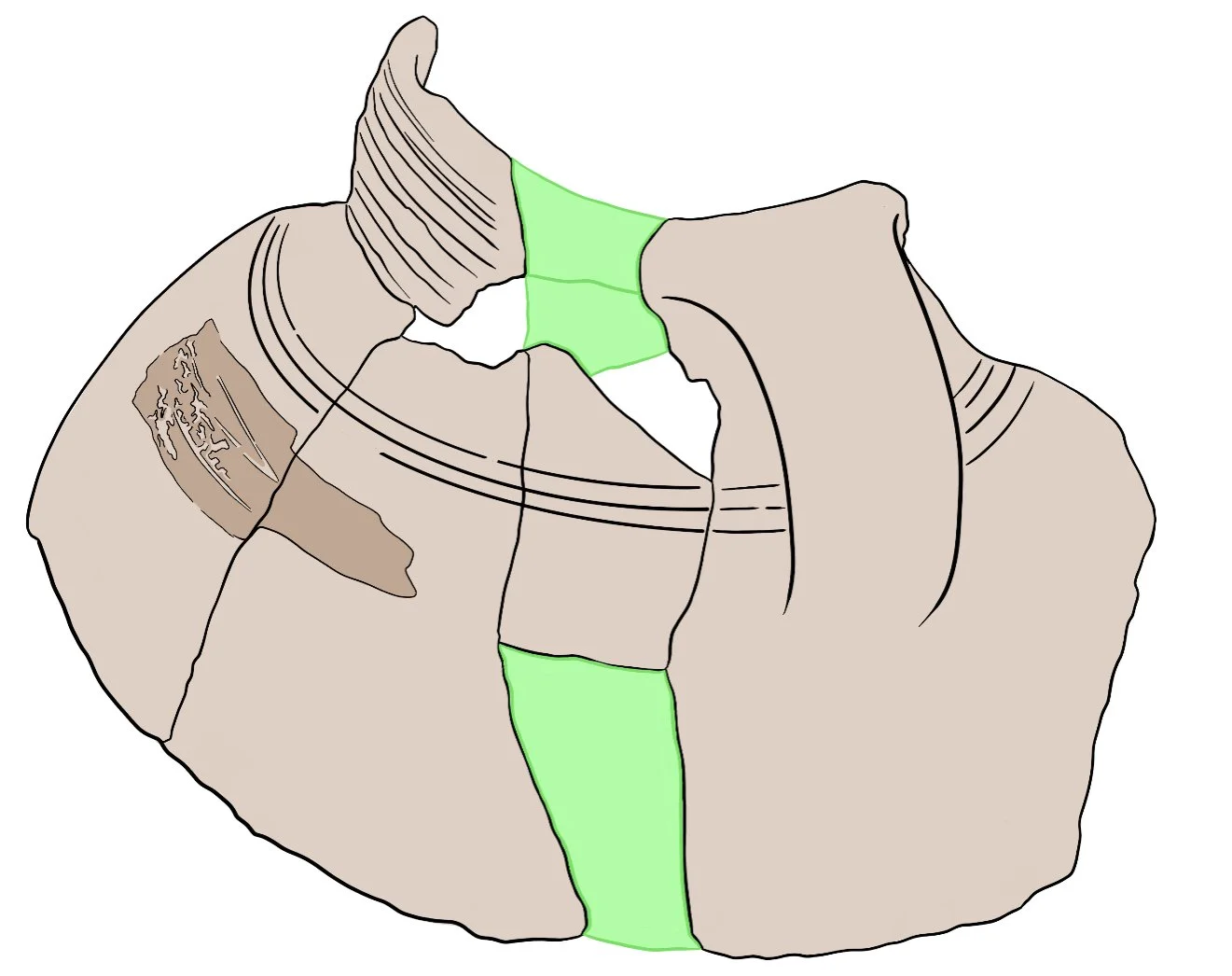

The fabric of the vessel is structurally sound with evidence of wear on edges of sherd fragments. The object is broken into five fragments that all have the ability to join to one another. Four of the five fragments are currently joined. The portions of the vessel that remain are that of the rim, one handle and a small section of the upper body. Previous conservation has been performed on the object at multiple points in the past, likely with two separate adhesives to partially reconstruct the object. Small, symmetrical lines can be seen on the interior and exterior alluding to the object being wheel thrown.

Reconstruction & Repair:

In a solvent atmosphere using acetone and cotton, the object was supported by acid-free tissue in a polypropylene container and covered in cling film and aluminium foil to fully enclose the container in order to weaken and break down the old joins.

The object remained in the solvent atmosphere for 24 hours. The original tape adhesive residue that was initially present on the exterior of the object had evaporated off in the solvent atmosphere.

Excess adhesive that remained on the joins was removed using cotton swabs, acetone, and bamboo skewers under an optical microscope.

Once all previous adhesives were removed, four fragments of the objects were reconstructed using Paraloid B-72 (ethyl methacrylate co-polymer) concentration of 60% w/v in acetone.

The rim fragment had larger losses along the back, thus, Japanese tissue was impregnated with Paraloid B-72 (30% w/v in acetone) was used to reinforce the join along the back.

The final fragment (with the attached handle) was adhered after the loss compensation was created and connected to the object.

Loss Compensation:

Using a low fired surrogate ceramic, detachable fills were made by creating a heat set dental wax mould around the loss that was secured with green Frog Tape. Plaster of Paris was placed in the mould and allowed to set.

Once dry, the piece was removed from the location, then adhered into place using Paraloid B-72 (60% w/v in acetone). The surrogate proved successful in creating a two part fill.

For the original object, dental wax was applied to the loss to make a mould for the plaster with the assistance of a heat gun so that it better conformed to the curvature of the object.

Using plaster of Paris, the first fill near the base was made then attached to the vessel. Once attached, the fifth and final fragment of the object was reattached. The two part fill was completed afterward and attached using Paraloid B-72 (60% w/v in acetone).

Packaging:

Due to its curvature and shape, a support was made to protect the object from damage in storage and encourage safe handling.

A shallow tray was made using archival cardboard. A Plastazote (polyethylene foam) support was made that matched the curvature of the object, as well as a small support edge to keep it securely upright.

The Plastazote was covered in Tyvek (synthetic flash-spun polyethylene fibres).