Great Britain Indian Department Papers

Project Duration: 160 hours

Provenance:

The Great Britain Indian Department papers are a collection of 51 documents that encompass Native American relations with the Department of Indian Affairs between the years 1753 and 1795. William Johnson, who served as the first superintendent of Indian Affairs from 1756-1774 was both the writer or recipient of nearly half of the papers, and served as the head of many important decisions regarding territorial disputes, trade, and issues between Native Americans and neighbouring British settlements. Subjects in the collection encompass treaties, negotiations, reports, and diplomacy that covered the French and Indian War and the American Revolution.

Due to the collection’s popularity among professors, students, and scholars around the world, a majority of the Great Britain Indian Department papers were in need of a variety of treatments in order for them to be safely utilized in the future. These documents hold valuable information regarding the understanding of British and Native American affairs as well as transcribed knowledge depicting the lifestyles and governing in the Six Nations. The Great Britain Indian Department Collection holds great monetary value and high research value to the Clements Library, therefore, the conservation of this collection is a very high priority.

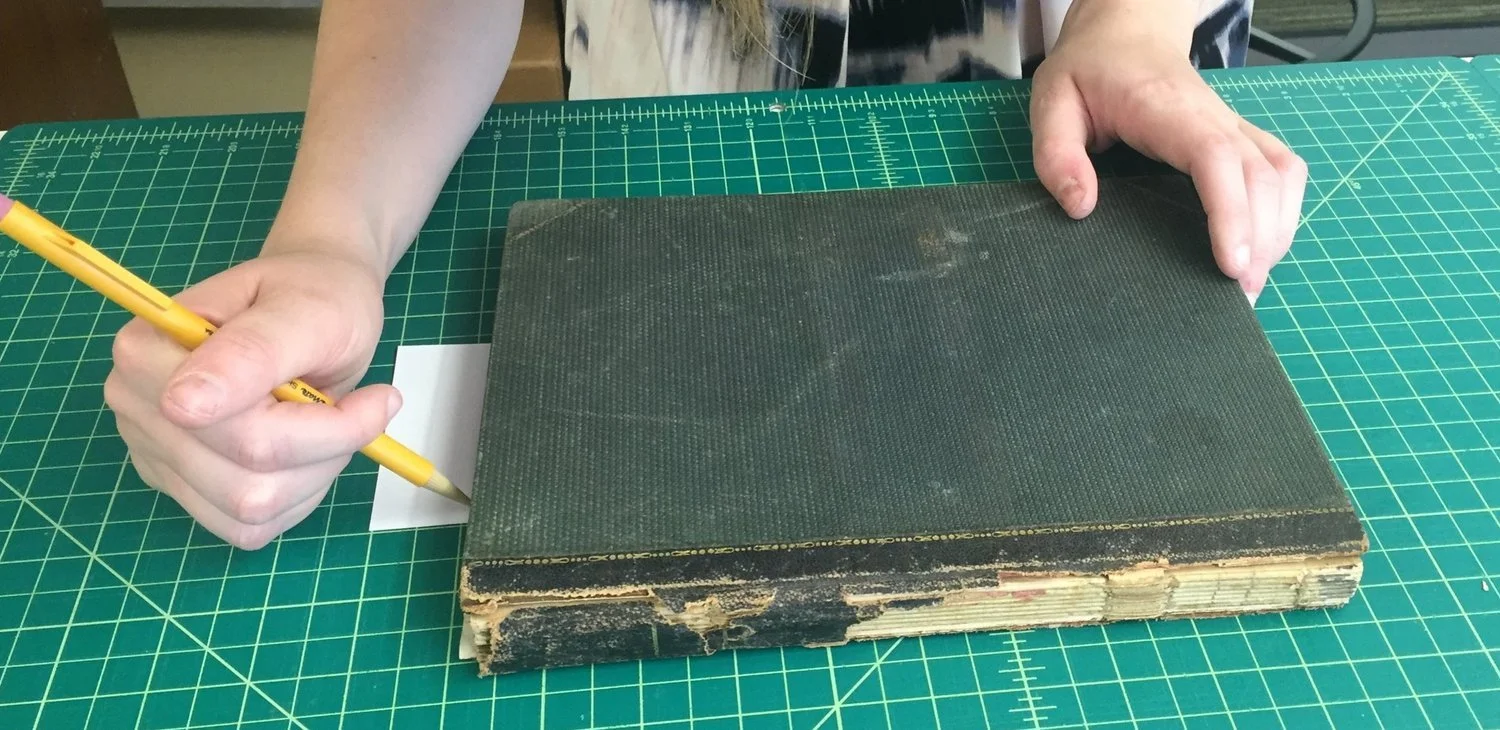

Condition: The collection contains 51 manuscript documents, some are single sheets, some are folded, and some are bound. All documents were written with iron gall ink. Almost all of the paper is very fragile, thinner, weak, especially around the fore edges. Six contain red wax seals, six documents have voids which compromise strength, and three items are sewn/bound. One of the three bound items is made up of two signatures, thirty leaves in total. The corners of many of the leaves are curled and weak. There is a remnant of a front or back cover – heavily soiled, extremely fragile and torn.

Encapsulation of Documents

Two sheets of Polyester were cut slightly larger than the document’s proportions.

Using a Polyester Welder, the two sheets of Polyester were heat sealed on two sides.

The document was inserted into the Polyester sleeve on a carrier sheet and the remaining two sides were sealed, completely encapsulating the document.

Lining:

The condition of each document was assessed.

Depending on the condition of the document, one or two sheets of Japanese tissue were cut.

An ink test is performed on a small region of text to confirm if ink was water soluble.

The document was wetted with deionized water and flattened.

A thin layer of wheat starch paste was applied in a thin, even layer to the document.

Japanese tissue was carefully applied to the surface of the document and evenly flattened to remove and rippling or folds.

Document was transferred to press between interleaving tissue and blotter blocks.

Document was left to dry for four days in press.

Once dry, document was removed from press and excess Japanese tissue was trimmed from edges.

Documents Possessing Wax Seals

Similar to lining process, each document was assessed with the location of each wax seal noted.

Two small sheets of Hollytex interleaving tissue were cut to fit snugly overtop of the seals during lining.

Lining of document proceeded with regions possessing wax seals not brushed with wheat starch paste.

Before applying Japanese tissue, Hollytex cutouts were placed overtop of seals to prevent tissue from attaching inside of the press.

Additional support was constructed to prevent seals from being damaged.

Document was placed in press until fully dry.

When removed from press, excess tissue was trimmed off of edges.

Using a razor or thin spatula, Hollytex covering seal was carefully removed from document.

Using methyl cellulose paste, any lifted tissue around seal was re-adhered to document so that is laid smoothly.

Treatment of Two Bound Journals:

The sewing on both the inner and outer leaves of each journal was photo-documented so that the stitching could be accurately replicated.

Each sewn item was paginated in pencil prior to dis-binding to sustain the accurate order of the leaves.

The journals were disbound – the thread was carefully snipped in between every sewing station and gently pulled with tweezers.

A piece of Japanese tissue was cut to fully line one side of each leaf, while 3/8 inch guards were cut to line the verso of each leaf at the fold to support the resewing.

The lining process proceeded.

Once the repairs were attached, interleaving tissue was placed on both sides of the document.

The blotter stack was comprised of three cotton blotter sheets between each document and Hollytex layer.

Once completely dry, each leaf was re-folded using a bone folder.

Each sewn item was collated, and carefully re-sewn using the original sewing perforations and following the original sewing style.

Documents Possessing Voids:

Similar to the lining process, each document was assessed and the location of each void is documented.

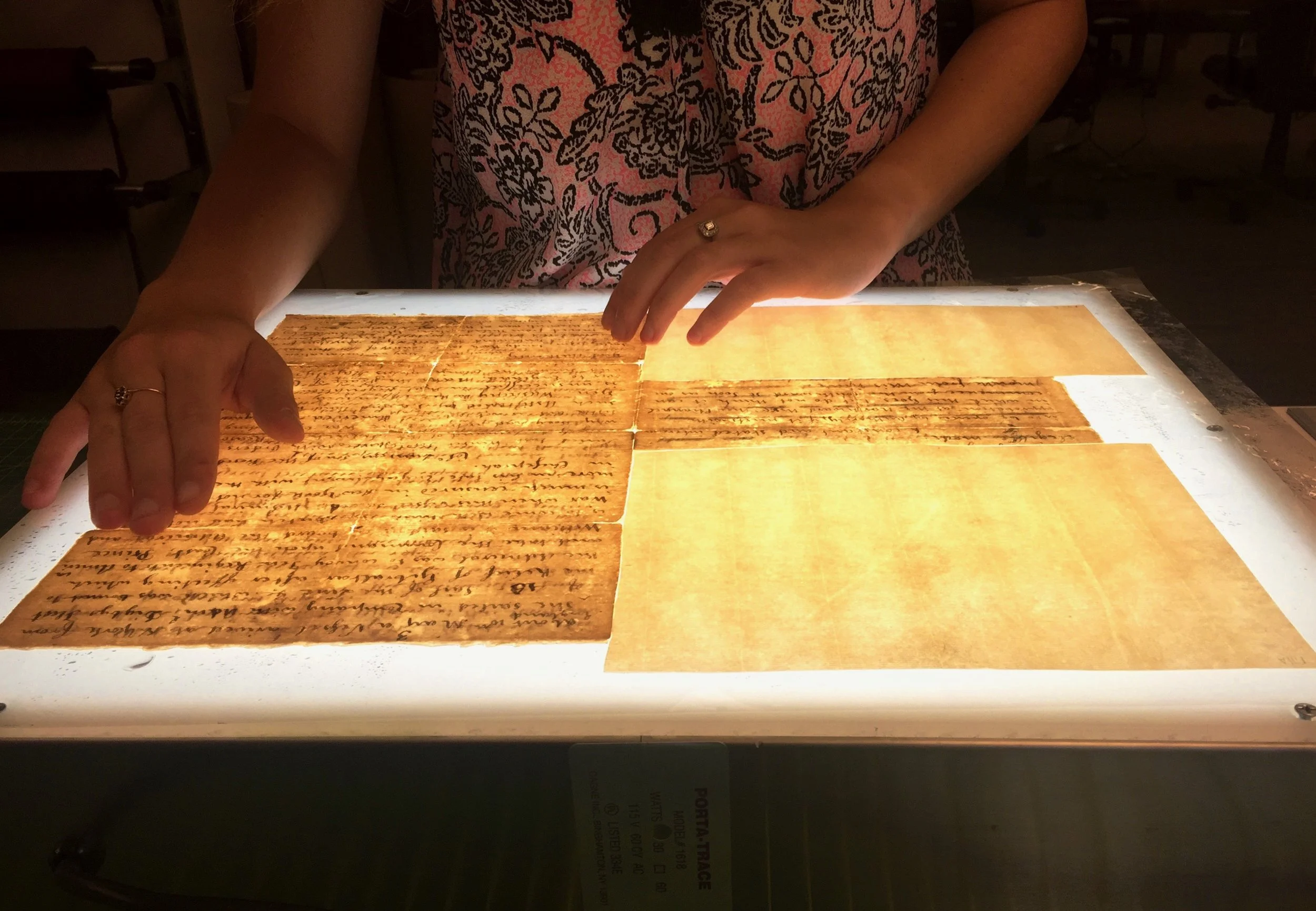

The document was placed on a light table.

A piece of paper that matched as closely as possible the characteristics of the original paper in weight, color, and style is chosen to fill the void.

Placing the new paper over top of the document, the fill was carefully traced to match the contours of the void, paying attention to aligning chain lines as well.

The fill was cut out and set aside while the lining process proceeded.

In these instances, one side of the document received full lining and the verso received a Japanese paper lining piece which carefully covered the fill and extended onto the document about 1/8 of an inch.

The document and the fill are wetted and placed on the polyester carrier sheet and pasted. The full lining was applied.

Paste was then carefully applied to the fill and extended 1/8 of an inch onto the document and the small piece of Japanese tissue was laid onto the area.

Once the repair tissue was attached, a single sheet of Hollytex interleaving tissue was placed over this side to completely cover the document and Japanese tissue linings.

Treatment of Large Bound Journal:

Each individual leaf in the journal was assessed for voids, tears, or detritus. After, the journal was paginated to retain its original order later on.

The sewing on both the inner and outer leaves of each signature in the journal was photo-documented so that the stitching could be accurately replicated.

The journal were carefully disbound, separating the first and second signature from one another. The cover also removed and encapsulated with its original thread.

For the first leaf of each signature, pieces of Japanese tissue were cut to fully line both sides of each leaf. A large amount of small triangles of Japanese tissue were also cut for any corners that would need reinforcing during washing and rinsing.

The first leaf of each signature had voids present, so fills were cut for them using paper of similar weight, quality, and color.

Each side first leaf of each signature was fully lined, with its fill inserted into the according void and placed in the press between interleaving tissue and blotters for 5 days, with blotters changed daily.

Other leaves were placed in a deionized water bath and left to soak until fully relaxed.

Once completely saturated with water, each document was taken out of the bath using interleaving tissue and its corners were assessed for any weak points.

If weak points were found, corners were reinforced with small triangular shaped Japanese tissue on both sides.

Each leaf was placed in the press between interleaving tissue and blotters to dry for five days, with blotters being changed daily.

Once all leaves were washed and fully dry, the pages were reassembled in their correct order and prepared to be re-sewn.

Journals were stored in protective sleeves made of archival card-stock.